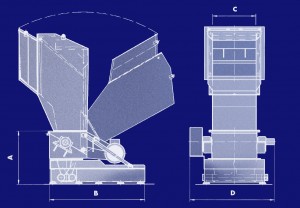

Design of NEUE HERBOLD granulators

Design of NEUE HERBOLD granulators

The rotors of the NEUE HERBOLD granulators type SM are equipped with double cross cutting technique. Both the rotating knives, as well as the stator blades in the mill housing are placed to each other at an angle. This technique ensures a targeted constant gap over the entire wide of the working surface and also ensures effective cutting. Simultaneously, the noise level is significantly reduced.

Housed in pillow block bearings and separate from the grinding chamber is the rotor shaft . A secure separation from the material to be crushed, and the prevention of leakage of dust particles from the grinding chamber is thereby ensured. By shatterproof welded steel construction of the mill housing, this holds in continuous operation the exceptional stress. Optionally, the housing can be lined with replaceable wear plates.

Alternatively, these as wet execution (wet granulator / wash mill) available.

Applications of NEUE HERBOLD granulators

To be emphasized are the diverse applications of these granulators. These mills can be equipped with different rotors. Suitable rotor variants are available and can be used for:

- size reduction of massive start-up lumps

- size reduction of massive profiles

- size reduction of bottle crates

- size reduction of massive purgings

- size reduction of PA-fibers

- size reduction of rubber bales

- size reduction of film packets

- size reduction of general plastic scrap with extremely wall thicknesses

- size reduction of voluminous hollow parts such as containers and crates

The different needs of a modern recycling plant to be covered by this type of mill.

Advantages of NEUE HERBOLD granulators

- universal application useage

- reduced space requirement due to compact design

- energy-saving size reduction

- low noise level due to double-cross cutting knife configuration

- easy cleaning due to “clam shell opening” characteristics

- higher through put rates

- reduced down time for rotor and stator knife replacement due to pre-adjusted knives

Video – Size reduction of PVC profile waste

Technical specifications of NEUE HERBOLD granulators